What is custom Screen printing

Screen printing is a technique used to make custom-designed T-shirts, koozies, bags and other products. During the screen printing process, a mesh-based stencil is used to apply ink to the item. Here’s a summary of the basic steps:

We take your artwork (or design it for you).

We create a film positive transparency of the artwork

Using the film positive, we create a screen. Each screen is made of polyester mesh stretched onto a frame (usually made of wood or aluminum). The screen is prepared by using emulsion (a light-sensitive liquid), the film positive, and a special light.

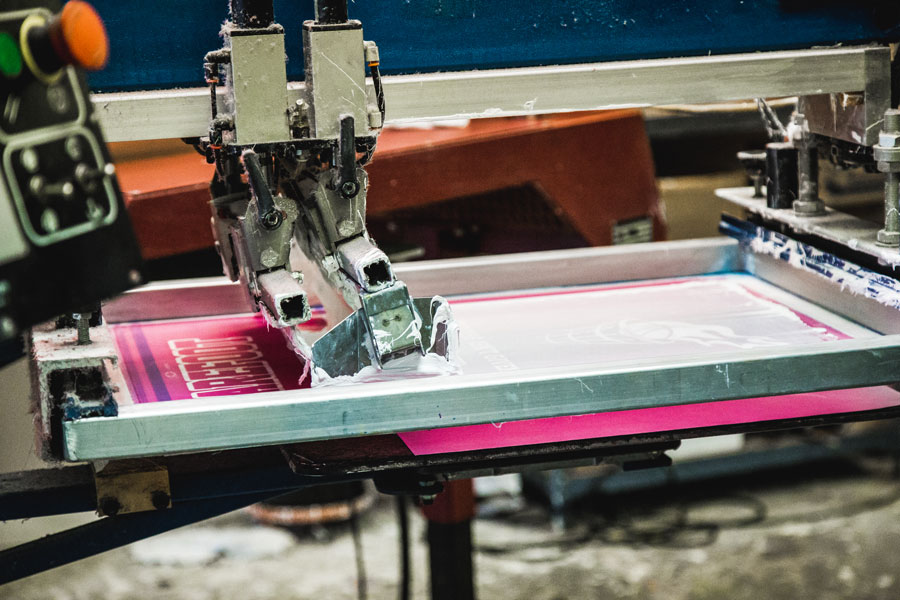

Your screen is inserted into the printing press, squeegees are locked in, and the ink is applied. Then your item is lined up in a perfectly flat position on the pallet.

The press raises the item to the screen, and the squeegees push ink through the openings in the mesh screen – printing your chosen design onto the item with ink.

The item is dried so the ink cures, and we’re done!

Standpoint

3400 Bernie Anderson Ave, Fort Worth, TX 76116

(817) 735-8511